یک بسته بندی برجسته نه تنها به طراحی منحصر به فردی برای جلب توجه نیاز دارد، بلکه به کاربردی دقت و صنعت نیز نیازمند است تا ارزش به آن بخشیده شود. بعد از اینکه، بسته بندی تیانلی به شما تفسیر دقیق چندین تکنیک تولید بسته بندی را ارائه خواهد داد، همراه در کشف این موضوع که این تکنیکها چگونه ارزش کلی بسته بندی را به طور قابل ملاحظه ای افزایش میدهند.

چاپ چهار رنگی

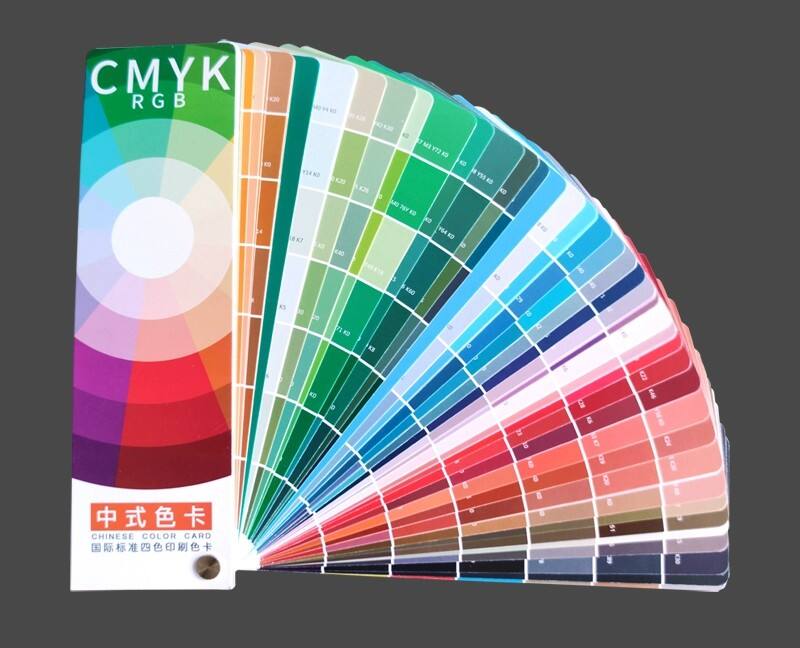

آیا هرگز به این فکر کردهاید که تصاویر زیبا و شبیه به واقعیت در جعبهها چگونه ایجاد میشوند؟ پاسخ در دنیای چاپ چهار رنگی وجود دارد. چاپ چهار رنگی، که همچنین به عنوان چاپ CMYK شناخته میشود، این فرآیند چاپ گستردهای است که برای دستیابی به تکثیر رنگی ساطع و واقعبینانه ضروری است. با استفاده از مدل رنگی که چهار رنگ حبر – سیان، مگنتا، زرد و سیاه (CMYK) – را ترکیب میکند، این تکنیک به اجرای ترکیب رنگی دقیق برای نتایج دقیق کمک میکند.

چاپ چهار رنگی که به چاپ CMYK نیز معروف است، نقش مهمی در ایجاد تصاویر با کیفیت بالا و وضوح استثنایی دارد. این شامل یک سری مراحل از جمله اصلاح رنگ، بررسی و استفاده از نرم افزار تخصصی برای جداسازی رنگ است. با کمک چاپگرهای پیشرفته و توجه دقیق به وضوح تصویر و فضای رنگ، این روش اطمینان می دهد که هر جزئیاتی به خوبی ثبت شده است. جوهر های CMYK برای تولید خروجی چاپی استفاده می شوند، که اجازه تولید دقیق رنگ های نقطه ای و طیف گسترده ای از رنگ های CMYK را می دهد.

چاپ نقطه ای

چاپ نقطه ای یک فناوری چاپ منحصر به فرد است که از جوهر های مخلوط شده ویژه برای تولید دقیق یک رنگ خاص استفاده می کند و اطمینان حاصل می کند که ارائه هم پر جنب و جوش و هم کامل است. در مقایسه با روش مخلوط کردن چاپ چهار رنگی، چاپ نقطه ای می تواند تفاوت های ظریف رنگ را با دقت بیشتری به دست آورد و بیان دقیق تر رنگ را به دست آورد.

در چاپ نکتهای، بستهبندی تیانلی معمولاً از رنگهایی مثل طلای ویژه و نقره ویژه استفاده میکند که به بستهبندی یک جنس خاص و لمعان میدهد. هنگامی که طراحی بستهبندی نیازمند دقت بالا در رنگ و روشنایی است، طراحان معمولاً از چاپ نکتهای برای تحقق ایدههای خلاقانه خود استفاده میکنند.

برای تضمین دقت و هماهنگی رنگ، طراحان معمولاً در زمان انتخاب رنگهای نکتهای به کارت رنگ پانتون بینالمللی مراجعه میکنند. با این حال، توجه دادن ضروری است که چاپ نکتهای نمیتواند مستقیماً اثرات گرادیان را تحقق بدهد. اگر طراحی بستهبندی نیاز به اثر گرادیان داشته باشد، طراحان باید فناوری چاپ چهار رنگی را ترکیب کنند و با قرار دادن لایههای رنگی، اثر گرادیان را شبیهسازی کرده و طراحی اصلی را به کاملی ارائه دهند.

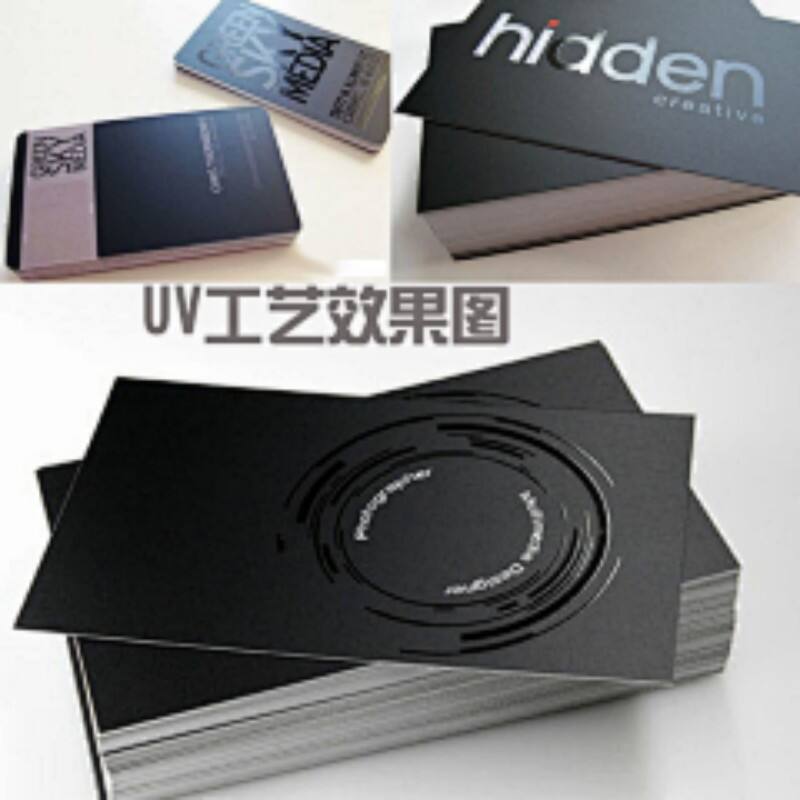

چاپ UV

فناوری چاپ UV یک فرآیند چاپ کارآمد است، به ویژه مناسب برای افزایش جلیل محلی بخشهای کلیدی مطالب چاپی. از طریق تابش نور فرابنفش، مواد چسبنده UV میتوانند سریع خشک شوند و پخته شوند که علاوه بر افزایش سرعت تولید، حس سهبعدی و لایهبندی الگوهای محلی را به طور قابل ملاحظهای افزایش میدهد. UV شفاف و UV خاموش دو درمان محبوب در چاپ UV بستهبندی تیانلی هستند که میتوانند با توجه به نیازهای طراحی اثرات بصری مختلفی را نمایش دهند. UV شفاف به بستهبندی یک لمعت فراوان میدهد، در حالی که UV خاموش یک متنی خاص و نرم به آن میبخشد که باعث میشود بستهبندی دقیقتر شود و نیازهای کیفیت بالا مصرفکنندگان را در زمینه ظاهر محصول برآورده کند.

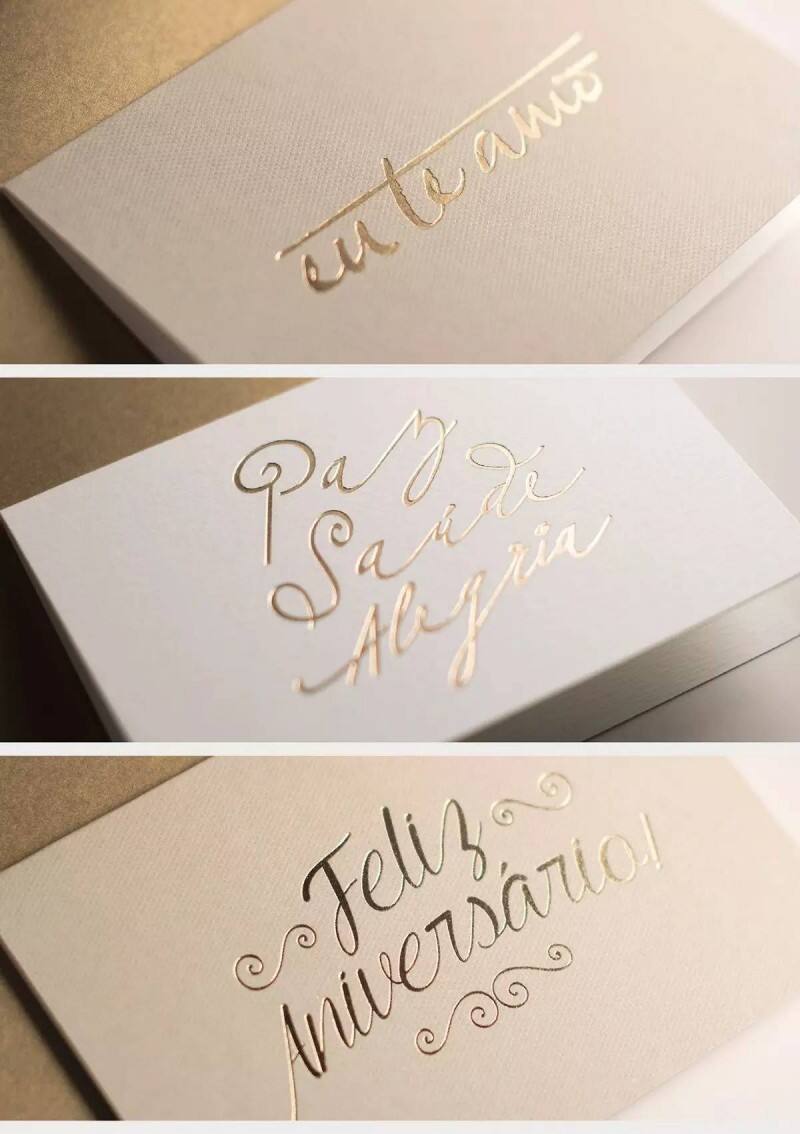

فويلچاپ گرم

فناوری چاپ حرارتی بر اساس اصل منحصر به فرد خود از انتقال فشار حرارتی، با مهارت لایه آلومینیوم را از الکترود آلومینیوم به سطح محصول انتقال میدهد و در نتیجه به بستهبندی یک اثر تابنده فلزی منحصربهفرد میدهد. این فرآیند چاپ نه تنها انعطافپذیر و قابل تغییر است، بلکه از الکترود آلومینیوم با رنگهای مختلفی مانند طلایی، نقرهای، قرمز، سبز و آبی به عنوان مواد اولیه استفاده میکند و همچنین میتواند بر اساس نیازهای طراحی، اثرات فلزی جذابی روی سطح بستهبندی ایجاد کند. از طریق کاربرد فناوری چاپ حرارتی بستهبندی تیانلی، درجه کلی و ارزش بستهبندی به شکل قابل توجهی افزایش یافته و آن را در میان بسیاری از محصولات متمایز میکند.

استخراج/غرزکوبی

این فرآیند از مجموعهای از الگوهای konk و konv با الگوهای مثبت و منفی متناظر استفاده میکند، زیرstrate را بین آنها قرار میدهد و سپس فشار بیشتری اعمال میکند تا بخشی شبیه به نقش عمقی ایجاد کند و در نتیجه لایهبندی و حس سهبعدی بستهبندی را افزایش دهد. بستهبندی تیانلی بر این باور است که این فرآیند میتواند بستهبندی را دقیقتر و لوکستر کند و ارزش اضافی محصول را افزایش دهد.

چاپ سیلکاسکرین

چاپ صفحهای یک فرآیند چاپ منحصر به فرد است که از طریق فشار دقیق مهرهی چاپ، از طریق شبکهای که برای این منظور ساخته شده و دارای سوراخهای گرافیکی است، مواد چاپی را به سطح زیربنایی منتقل میکند. این روش چاپ میتواند طیف گستردهای از رنگها را نشان دهد و طراحان میتوانند با توجه به استاندارد بینالمللی کارت رنگ پانتون، رنگ مناسبترین را انتخاب کنند. هرچند که چاپ صفحهای نمیتواند به طور مستقیم اثرات چاپ گرادیان را به دست آورد، اما روش چاپ منحصر به فرد آن میتواند اشباع رنگ بالا و لایهبندی رنگ قوی را تضمین کند. بنابراین، در طراحی بستهبندی، چاپ صفحهای میتواند اثرات رنگی روشن و کاملی ارائه دهد که جذابیت بصری بستهبندی تیانلی را به شدت افزایش میدهد و محصول را بر روی رف برجسته میکند.

ایجاد بستهبندیهای کیفیتمند بدون تنظیمات حرفاگری دقیق امکانپذیر نیست که اطمینان میدهد ایده طراحی به طور کامل و دقیق منتقل میشود. برای سفارش جعبهای خاص از ما تماس بگیرید.

اخبار داغ

اخبار داغ