In an era where sustainability and functionality are paramount, paper packaging boxes have emerged as a preferred choice for industries ranging from food to luxury goods. The materials used in these boxes play a critical role in balancing environmental responsibility with practical performance.This article delves into the common materials, their properties, and their applications in modern packaging.

1. Kraft Paper: The Sturdy Classic

Kraft paper, derived from wood pulp through the sulfate pulping process, is renowned for its durability and natural appearance. Its high tear resistance and tensile strength make it ideal for heavy-duty packaging, such as shipping boxes or industrial containers. Unbleached kraft paper retains its brown hue, offering a rustic aesthetic while minimizing chemical processing.

Increasingly, recycled kraft paper is being adopted to enhance sustainability without compromising structural integrity.

2. Corrugated Fiberboard: The Protective Workhorse

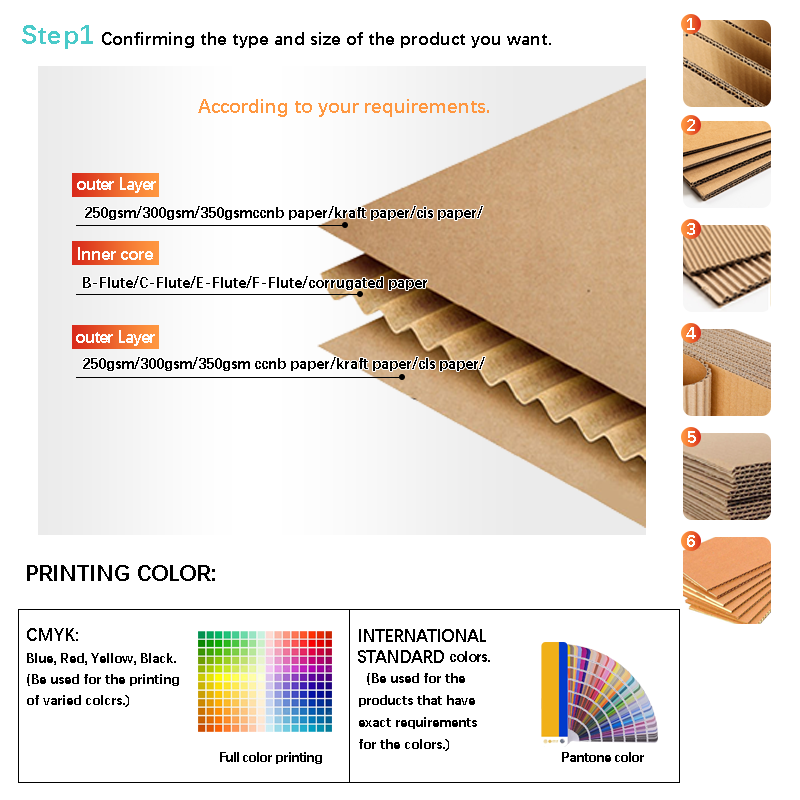

Composed of fluted corrugated sheets sandwiched between linerboards, corrugated fiberboard provides exceptional cushioning and shock absorption.The air pockets in the fluted layer act as insulators, protecting fragile items during transit.Variations in flute sizes (A-flute, B-flute, etc.) allow customization for different weight capacities.This material dominates e-commerce packaging due to its lightweight nature and recyclability.

3. Cardboard/Paperboard: The Versatile Performer

Often confused with corrugated board, solid paperboard (or cardboard) is a thick, single-layer material used for retail boxes, cosmetic packaging, and food containers.Its smooth surface is ideal for high-quality printing, enabling brands to create visually appealing designs.Food-grade paperboard with polyethylene (PE) or polylactic acid (PLA) coatings is widely used for liquid cartons and takeaway boxes, though uncoated versions remain easier to recycle.

4. Molded Pulp: The Eco-Innovator

Made from recycled paper or agricultural waste, molded pulp is gaining traction for its circular economy potential.This material is heated and pressed into custom shapes, creating protective inserts for electronics or compostable food trays.Its porous structure and biodegradability make it a star in sustainable packaging solutions, particularly for single-use items replacing plastics.

5. Coated Papers: The Premium Touch

For luxury packaging, clay-coated or art papers add a refined finish.These coatings enhance color vibrancy and provide water-resistant surfaces.While traditionally less eco-friendly due to coating materials, new plant-based coatings and UV-curable inks are reducing environmental impacts. Metallized papers and embossed textures further elevate the unboxing experience for high-end products.

Sustainability Considerations

Modern paper packaging prioritizes:

- Recycled content: Post-consumer waste (PCW) fibers reduce deforestation.

- Certifications: FSC or PEFC labels ensure responsible forestry practices.

- Water-based adhesives: Replace plastic tapes and toxic glues.

- Minimalist designs: Reducing ink usage and material waste.

Challenges & Innovations

Despite advancements, limitations persist.Moisture sensitivity and weight restrictions drive research into hydrophobic nanocoatings and hybrid materials.Emerging trends include:

- Mycelium-reinforced paper: Boosting strength with fungal networks.

- Edible coatings: For zero-waste food packaging.

- Digital watermarking: Facilitating recycling through smart labeling.

Paper packaging materials are evolving beyond their traditional roles, marrying ecological consciousness with technological innovation.As consumer demand for sustainability grows, the industry continues to reinvent paper-based solutions—proving that this ancient material remains at the forefront of modern packaging challenges.