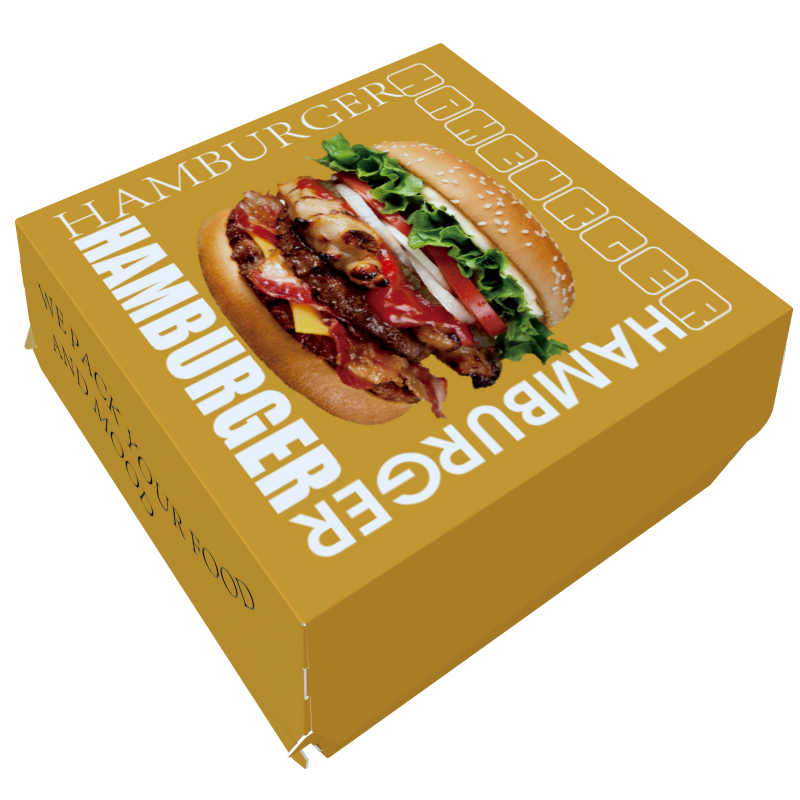

Suitable brand style

When customizing high-end packaging boxes, choosing a packaging style that is suitable for the brand is very important for brand image and product attention. This year, minimalist design style has been very popular in the packaging industry, but it is not suitable for every brand.

Minimalist design style is to keep the use of design elements to a minimum. Therefore, no matter what product you are, there are very few design elements that attract customers' senses. However, minimalist design style can maximize the display of brand elements and product information in front of potential customers, and can attract customers' attention through the advantages of the brand and product.

The biggest characteristic of luxury design elements is their ability to directly impact customers' senses. So, whether it's color, texture, pattern, etc., they all need to be used extensively. High end materials are also required for the selection of packaging boxes.

Optimal size

To choose the right size box, you first need to measure the dimensions of the product you’re boxing.

All you need to do is measure the length, width, and height of the product with a straight ruler. Once you have those measurements, add fractions of an inch or centimeter if you want some wiggle room. You only want your box to be as big as you need it to be.

Does your product require cushioning such as bubble wrap or kraft paper? Don’t forget to account for the extra room these require when determining the final measurements.

Note: keep in mind that any box manufacturer will ask for the inside dimensions of the box you're looking for, not the outside. This is because for thicker materials, the inside and outside dimensions will be slightly different.

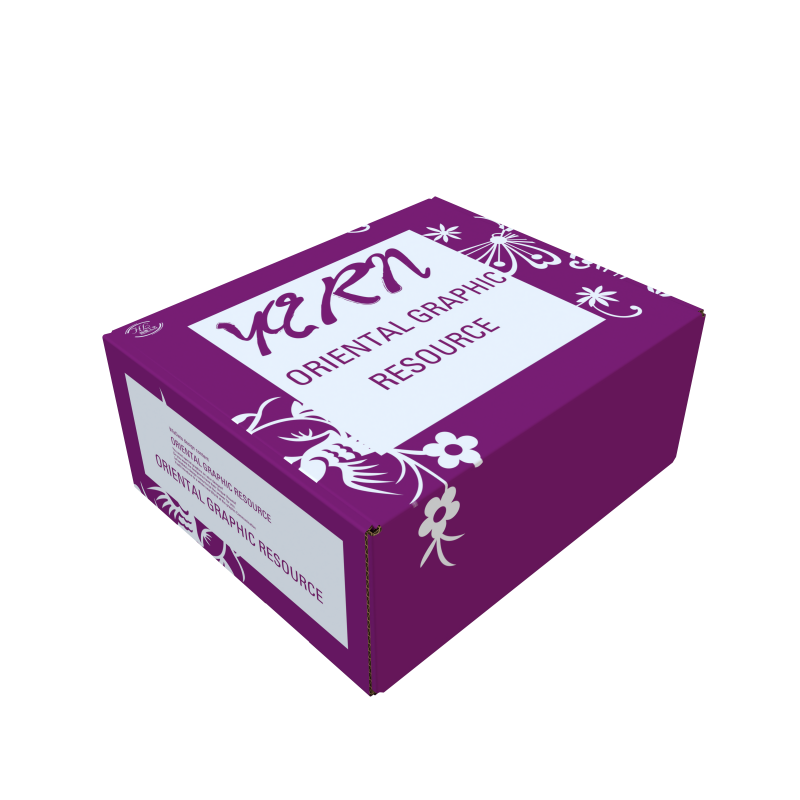

How to choose the printing method for boxes

You have a lot of things to consider when packaging a product. One of the first choices you make should be the way you want your design printed. You have a few basic print options, including:

Beyond choosing the best printing method for your custom boxes, you also need to decide on a material that helps you show off your products in a catchy way. The best material for packaging offers flexibility and versatility to bring out the desired colors and artwork as you envisioned them. There are two common packaging materials for printing worth looking into:

Kraft boxes have a typical matte cardboard feel and brown color that’s perfect for printing minimal designs in darker colors. Packaging designs on kraft corrugated boxes are best for brands going for a rustic and eco-friendly image because they’re 100% recyclable and biodegradable. They work best with dull and dark colors such as black, navy blue and jungle green because lighter colors are altered by the natural brown color on the boxes to appear earthy and flat.

White corrugated boxes provide a clearer and easier canvas to print on any colors and complex artwork and designs. They offer more design flexibility when you’re looking to create vibrant and unique designs. Additionally, they work better with bright, saturated and neutral colors than kraft corrugated boxes, keeping them true to their natural hues and lending them the perfect vibrancy and contrast.

Standard white corrugated cardboard boxes create a dreamy unboxing experience for customers that they won’t resist sharing on their social media pages. Unfortunately, white corrugated boxes contain very small amounts of recycled materials and are not the most sustainable or eco-friendly packaging option. But they give your packaging an elegant and sophisticated feel, providing customers with additional perceived value.

Sustainability