Hat boxes have evolved from simple storage containers into sophisticated packaging solutions that elevate brand identity and customer experience. Modern boutique businesses recognize the power of custom hat boxes to create memorable unboxing moments while protecting their precious merchandise. These specialized packaging solutions offer endless customization opportunities, from material selection and structural design to branding elements that reflect your boutique's unique personality. Whether you're packaging luxury millinery, fashion accessories, or premium gifts, the right hat boxes can transform your product presentation into a marketing masterpiece that customers will treasure long after purchase.

Understanding Custom Hat Box Design Fundamentals

Material Selection for Premium Presentation

The foundation of exceptional hat boxes lies in choosing the right materials that balance durability, aesthetics, and sustainability. High-quality cardboard remains the most popular choice, offering excellent printability and structural integrity while maintaining cost-effectiveness for boutique operations. Rigid paperboard provides superior protection for delicate items, while corrugated cardboard offers enhanced cushioning for shipping applications. Some luxury boutiques opt for eco-friendly kraft paper or recycled materials to align with environmental consciousness, creating hat boxes that appeal to sustainability-minded customers.

Premium materials like textured paper, linen-wrapped surfaces, or specialty finishes can dramatically enhance the perceived value of your hat boxes. These materials create tactile experiences that customers associate with quality and attention to detail. Consider the weight and thickness of your chosen material, as heavier stocks convey luxury while lighter options may be more practical for shipping considerations. The material selection directly impacts printing quality, so ensure compatibility with your intended decoration methods.

Structural Engineering for Optimal Protection

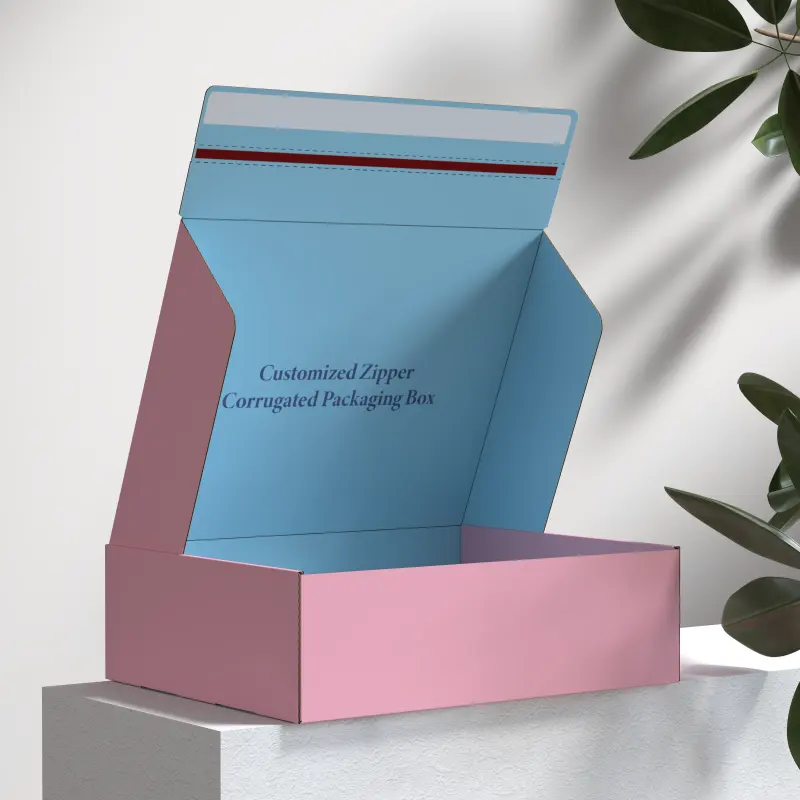

Effective hat boxes require thoughtful structural design that accommodates various hat styles while maintaining shape integrity during handling and storage. Traditional round hat boxes work well for most millinery applications, but square or rectangular formats may better suit modern fashion accessories or multiple item packaging. Internal dividers or foam inserts can prevent movement and crushing, particularly important for delicate or structured pieces.

Consider the opening mechanism carefully, as this affects both user experience and manufacturing costs. Lift-off lids provide classic elegance and full access to contents, while hinged designs offer convenience and prevent lid separation. Some boutique hat boxes incorporate magnetic closures for premium appeal, though these increase production costs. Ensure adequate depth to accommodate various hat heights while avoiding excessive empty space that allows movement during transit.

Branding and Visual Design Strategies

Logo Placement and Brand Identity Integration

Strategic logo placement on hat boxes creates powerful brand recognition while maintaining aesthetic balance. The lid center traditionally serves as the primary branding location, though side panels and interior surfaces offer additional opportunities for brand messaging. Consider logo size relative to box dimensions, ensuring visibility without overwhelming the overall design. Embossed or debossed logos add tactile luxury, while foil stamping creates eye-catching metallic accents that convey premium positioning.

Brand colors should integrate seamlessly with your overall marketing strategy, creating consistent visual identity across all customer touchpoints. Custom hat boxes serve as mobile advertisements, so ensure your color palette photographs well for social media sharing. Consider how your branding will appear in various lighting conditions and against different backgrounds, as customers often display attractive packaging in their homes or share unboxing experiences online.

Typography and Messaging Optimization

Typography selection for hat boxes requires careful balance between readability and brand personality. Script fonts may convey elegance for luxury boutiques, while clean sans-serif options suit modern, minimalist brands. Ensure sufficient contrast between text and background colors for easy reading, particularly for smaller text elements like care instructions or website addresses. Consider the viewing distance and angle at which customers will typically see your hat boxes.

Messaging beyond basic branding can enhance customer engagement and perceived value. Thank you notes, care instructions, or brand stories printed inside lids create delightful discoveries during unboxing. QR codes linking to digital content, styling videos, or exclusive offers bridge physical packaging with digital experiences. Keep messaging concise and purposeful, avoiding clutter that detracts from the overall aesthetic appeal of your custom hat boxes.

Production Techniques and Finishing Options

Printing Methods for Professional Results

Digital printing offers flexibility and cost-effectiveness for smaller runs of hat boxes, allowing for variable data printing and quick turnaround times. This method works well for boutiques testing new designs or offering personalized packaging options. Offset printing provides superior color accuracy and consistency for larger production runs, making it ideal for established boutiques with standardized packaging requirements. Screen printing offers vibrant colors and special ink effects, though setup costs make it more suitable for larger quantities.

Color management becomes critical when reproducing your brand colors accurately across different printing methods and materials. Work with experienced packaging suppliers who understand color matching and can provide reliable proofs before full production. Consider how different substrates affect color appearance, as the same ink may appear differently on various paper types or finishes.

Special Finishing Techniques for Luxury Appeal

Finishing techniques can transform ordinary hat boxes into premium packaging experiences that justify higher product pricing. UV coating provides protection while adding glossy highlights to specific design elements. Matte lamination creates sophisticated, fingerprint-resistant surfaces that feel luxurious to touch. Spot varnishing allows selective application of gloss or texture to create visual contrast and draw attention to key design elements.

Embossing and debossing create dimensional effects that add tactile interest to your hat boxes. These techniques work particularly well for logos, brand names, or decorative elements that you want to emphasize. Hot stamping with metallic foils creates striking accents that photograph beautifully for social media, though costs increase with coverage area and color complexity. Consider combining multiple finishing techniques for maximum impact, but maintain design balance to avoid overwhelming the overall aesthetic.

Size Optimization and Functionality Considerations

Dimensional Planning for Product Fit

Proper sizing ensures hat boxes provide adequate protection while minimizing material waste and shipping costs. Measure your products carefully, accounting for any tissue paper, protective wrapping, or branded accessories you plan to include. Allow sufficient clearance for easy product placement and removal without forcing, which could damage delicate items or create poor customer experiences.

Consider creating multiple size options to accommodate your complete product range efficiently. Standardizing on a few key dimensions can reduce inventory complexity while ensuring optimal fit for most items. Some boutiques design modular hat boxes that can accommodate single items or multiple pieces, providing flexibility for gift sets or bulk purchases. Calculate shipping dimensional weights to ensure your box sizes don't incur unnecessary surcharges from carriers.

User Experience and Functionality Features

Modern hat boxes should prioritize user experience through thoughtful functionality features. Easy-grip areas or finger cutouts facilitate handling, particularly important for larger or heavier boxes. Consider how customers will carry your hat boxes, especially if they're likely to be used as gift containers or shopping bags for extended periods.

Storage and reusability factors can add significant value to your custom hat boxes. Design elements that encourage retention, such as attractive interior printing or sturdy construction, extend your brand exposure beyond the initial purchase. Some boutiques include care cards or storage tips to help customers preserve both the packaging and contents, creating positive associations with your brand's attention to detail and customer care.

Cost Management and Production Planning

Budget Optimization Strategies

Balancing quality with cost-effectiveness requires strategic planning and clear priorities for your hat boxes project. Identify which elements most significantly impact customer perception versus production costs. Often, material quality and printing clarity matter more than expensive finishing techniques for building brand credibility. Consider phased implementation, starting with essential branding elements and adding premium features as sales volume justifies increased packaging investment.

Order quantity significantly impacts unit costs, but avoid over-ordering unless you have reliable sales forecasts. Some suppliers offer mixed runs of different sizes at quantity break pricing, allowing boutiques to optimize inventory levels while achieving better per-unit costs. Factor storage costs and shelf life into your calculations, as packaging materials can deteriorate or become obsolete if held too long.

Supplier Selection and Quality Control

Choosing the right manufacturer for your hat boxes requires evaluating capabilities, reliability, and quality standards. Look for suppliers with experience in boutique packaging who understand the importance of consistent quality and on-time delivery. Request samples of similar projects to assess print quality, construction integrity, and finishing capabilities before committing to large orders.

Establish clear quality specifications and approval processes to ensure your hat boxes meet expectations. Consider factors like corner sharpness, glue joint strength, and color consistency across the production run. Some boutiques implement incoming inspection procedures or work with third-party quality services to verify packaging meets specifications before accepting delivery. Building strong relationships with reliable suppliers can provide advantages in rush situations and access to new capabilities as they become available.

Market Trends and Future-Proofing Strategies

Sustainability and Environmental Considerations

Environmental consciousness increasingly influences packaging decisions, with customers actively seeking brands that demonstrate sustainability commitment. Eco-friendly hat boxes using recycled materials, water-based inks, and biodegradable coatings appeal to environmentally aware consumers while potentially reducing material costs. Consider designing for disassembly, making it easy for customers to separate different materials for proper recycling.

Sustainable packaging can become a competitive advantage when properly communicated to customers. Include recycling instructions or sustainability messaging on your hat boxes to highlight environmental benefits. Some boutiques partner with environmental organizations or participate in packaging take-back programs, creating additional customer engagement opportunities while demonstrating genuine environmental commitment.

Digital Integration and Technology Adoption

Modern hat boxes can bridge physical and digital experiences through technology integration. QR codes provide access to digital content, styling videos, or augmented reality experiences that enhance product value. NFC tags embedded in premium packaging can trigger personalized digital experiences when scanned with smartphones, creating memorable brand interactions that encourage social sharing.

Consider how your hat boxes will photograph for social media, as unboxing videos and posts provide valuable user-generated content. Design elements that create photogenic moments, such as revealing branded tissue paper or discovering hidden messages, encourage customers to share their experiences online. Track which design elements generate the most social engagement to inform future packaging developments and marketing strategies.

FAQ

What minimum order quantities should boutiques expect for custom hat boxes?

Most packaging manufacturers require minimum orders between 500-1000 units for custom hat boxes, though some specialized suppliers offer lower minimums for boutique businesses. Digital printing technologies have reduced minimum requirements compared to traditional offset printing, making custom packaging more accessible for smaller retailers. Consider starting with basic customization options to test market response before investing in premium features that require higher minimum orders.

How long does the design and production process typically take?

The complete process from initial design concepts to delivered hat boxes usually takes 3-6 weeks, depending on complexity and approval cycles. Design development and sampling typically require 1-2 weeks, while production and shipping add another 2-4 weeks. Rush orders may be possible for additional fees, but planning ahead ensures better pricing and quality control. Factor in potential revisions and approval delays when planning launch timelines for new products or seasonal campaigns.

What design files and specifications are required for production?

Manufacturers typically require high-resolution vector files (AI, EPS, or PDF) with all fonts outlined and images embedded at 300 DPI minimum. Provide exact dimensions, color specifications (Pantone colors for consistency), and detailed finishing instructions. Include dieline templates if available, or request them from your supplier to ensure proper design placement. Clear specifications prevent production delays and ensure your hat boxes meet quality expectations.

How can boutiques test packaging effectiveness before large-scale orders?

Start with small prototype runs or sample quantities to test customer response and identify potential improvements. Many suppliers offer sampling services at reasonable costs, allowing evaluation of materials, construction, and visual appeal. Consider A/B testing different design elements with small customer groups to gather feedback before finalizing specifications. Digital mockups and 3D renderings can help visualize concepts, but physical samples provide the most accurate representation of the final hat boxes experience.